A desiccant is a product or material that can be absorbs moisture from the air, thus reducing the humidity in a controlled environment and thereby protecting goods from moisture damage.

A desiccant is a product or material that can be absorbs moisture from the air, thus reducing the humidity in a controlled environment and thereby protecting goods from moisture damage.

Desiccant absorption characteristics

Physical absorption

Such desiccants absorb moisture physically by trapping the moisture inside its capillaries or its surface, yet the water molecules chemical properties remain unchanged, thus the moisture absorption process is reversible.

Typical physical absorption desiccants: silica gel, molecular sieve, etc.

Chemical absorption

Such desiccants absorb moisture and convert the resultant mixture to another substance by changing its chemical properties a process that is irreversible.

Typical chemical absorption desiccant: calcium chloride, magnesium sulfate, etc.

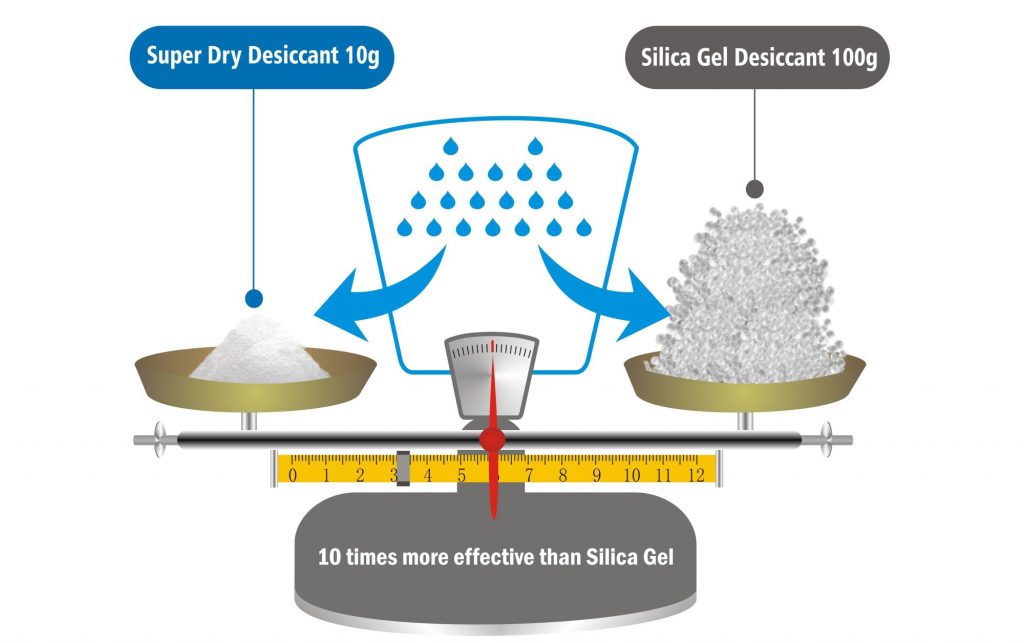

The quantity of comparison of desiccant used

The most common dessicants is use are silica gel and clay which only absorb from 10% to 27% of their dry weight, whereas Super Dry desiccant absorbs up to 300%.

The absorption rate of Super Dry desiccant is 8 times up to 15 times than the common desiccants.

For example, inside a hermetically seeled box of 1 cubic meter at 30°C and 80% RH, there are 24 grams of moisture. To absorb all the moisture inside the box, about 100 grams of high quality common desiccant are required but only about 10 grams of Super Dry desiccant are required. Furthermore this makes Super Dry extreamly cost efficient verses other type of desiccant.

Four common desiccant raw material ingredients and their main characterstics

| Desiccant | Description | Features | Absorption rate | Application TEMP |

| Calcium Chloride Desiccant | High purity CaCl2 as its main absorption agent | Chemical absorption, nontoxic and odorless; High moisture absorption ability | up to 700% | -5°C — 90°C |

| Silica Gel | SiO2 as the main ingredient, transparent and semi-transparent solid spheres | Physical absorption with mild reaction; Chemically stabe, relatively high mechanical strength; Granules with dry surface and no significant change in appearance after use; Reusable after oven drying. | 10% —27% | below 35°C |

| Clay | Also called montmorillonite desiccant, in powder or ball form | Additive-free, non-toxic, environmentally friendly | 15% —23% | below 50°C |

| Molecular Sleve | Crystalline aluminosilicate with homogeneous aperture and realatively large surface areas and selectively absorption | Recyclable, non-toxic, non-corrosive, chemically stable; Sensitive to environmental humidity, absorbs moisture even under ultralow humidity | 10% — 25% | can be used at high temperature |

Super Dry is the world’s leading supplier of desiccants and moisture damage prevention solutions. Super Dry products are widely used in virtually all the world’s major manufacturing industries during ocean transport. Super Dry was established in Singapore in 2000 by professionals with experiences in manufacturing, ocean transport and surveying. As of 2012, Super Dry has 3 factories, 1 R&D centre and over 40 offices worldwide. The Super Dry R&D centre in Shenzhen is the most advanced of its kind in the world utilizing the most sophisticated equipment and testing technology to ensure our products are the safest and effective available.

There is virtually no limit to the number of products that have received Super Dry protection during their transportation worldwide, they include furniture, garments, footwear, bags, handicrafts, electrical goods, toys, machinery, auto parts, metals, metal products, agriculture products, pharmaceuticals, etc. Super Dry aims to supply the most efficient and cost effective solutions for our clients in the continuing battle to eliminate moisture damage not only by supplying desiccants but also reviewing all facets of their manufacturing storage and shipping that may negatively impact the quality of their goods.

Super Dry is committed to the highest standards of quality control in all aspects of its operations to generate and ensure customers’ confidence and to maintain our competitive position in the global marketplace

To date, we won ISO 9001:2008 version of attestation and ISO 14001:2004 version of attestation. Quality management section of Super Dry is responsible for the regular check of quality management high quality. In environment protection aspect, we use non-toxic ingredients, safe packing materials and discharge no pollutants during production process.

Moreover, Super Dry has obtained certifications of REACH, RoHS, ECO, authoritative test reports of DMF free and absorption from SGS, TUV. Therefore, Super Dry is suitable in almost all major industries and its quality complies with all major global market standards especially EU and USA.

Showing all 4 results